Suku cadang excavator bucket tooth for sale

untu ember

Amarga ana akeh jinis suku cadang, kita ora bisa nampilake kabeh ing situs web. Mangga aran gratis kanggo hubungi kita kanggo tartamtu.

Kaluwihan

1. Kita nyedhiyakake produk asli lan aftermarket kanggo sampeyan

2. Saka pabrikan menyang pelanggan langsung, ngirit biaya sampeyan

3. Simpenan stabil kanggo bagean normal

4. Ing Wektu Pangiriman Wektu, kanthi biaya pengiriman sing kompetitif

5. Profesional lan ing wektu sawise layanan

Packing

Kothak karton, utawa miturut panyuwunan klien.

katrangan

Gigi ember excavator minangka bagean penting saka excavator, padha karo untu manungsa, nanging uga bagean sing rawan. Padha digabungake untu ember dumadi saka jog waos lan tip waos, lan loro disambungake dening batang pin. Amarga bagean saka ember waos nyandhang lan Gagal tip waos, mung ngganti tip waos.

Klasifikasi miturut lingkungan ing ngendi untu ember excavator digunakake. Untu ember excavator bisa dipérang dadi untu watu (digunakake kanggo bijih wesi, tambang, lan liya-liyane), untu obah bumi (digunakake kanggo ngeduk lemah, pasir, lan liya-liyane), lan untu runcing (digunakake kanggo tambang batu bara).

Aliran proses

Proses teknologi untu ember: pengecoran pasir, penempaan lan pengecoran presisi.

Pengecoran pasir: biaya paling murah, dene tingkat ketrampilan lan kualitas untu ember ora kaya casting presisi lan casting die forging.

Forging: biaya paling dhuwur lan pakaryan paling apik lan kualitas waos.

Casting presisi: Biaya moderat nanging syarat kanggo bahan mentah ketat banget, lan tingkat teknologi relatif dhuwur. Amarga úa, sawetara presisi casting ember untu duwe nyandhang resistance lan kualitas malah ngluwihi forging casting ember untu. Saiki, untu ember presisi minangka proses manufaktur utama kanggo untu ember ing pasar.

Forging ember untu nggunakake forging machinery kanggo aplikasi meksa kanggo kothong logam khusus, extruding lan mbentuk ing suhu dhuwur, nyaring materi kristal ing forging, lan nggawe plastically deformed kanggo njupuk sifat mechanical tartamtu. Logam kasebut bisa nambah strukture sawise ditempa. , Sing bisa mesthekake yen untu ember palsu duwe sifat mekanik sing apik, luwih tahan nyandhang lan umur layanan luwih suwe. Casting kanggo nyawiji logam ing suhu dhuwur, nambah bahan tambahan, inject model, lan njupuk casting sawise solidification. Casting sing diprodhuksi dening proses iki rawan kanggo pori-pori lan trachoma. Sifat mekanik, resistensi nyandhang lan umur layanan relatif apik. Forgings kurang.

Cara ngganti untu bucket excavator:

1. Untu ember kudu tetep landhep.

2. Untu ing loro-lorone ember umume luwih cepet tinimbang untu ing tengah ember. Nalika untu ing loro-lorone rusak luwih cendhek tinimbang untu ing tengah, posisi untu ing tengah lan ing sisih loro bisa diganti lan terus digunakake. Yen beda antarane dawa waos ing tengah lan waos ing loro ends tekan 2 kanggo 3 cm, iku kudu diganti.

3. Yen beda antarane dawa waos ing tengah lan dawa waos ing loro ends tekan 2 kanggo 3 cm, iku kudu diganti. Mangga ngganti untu ember ing wektu.

4. Priksa kanthi visual longgar lan nyandhang untu ember sadurunge nyambut gawe saben dina. Yen nyandhang untu ember ngluwihi watesan panggunaan, ora mung ngrusak kursi waos lan ember, nanging uga mengaruhi efisiensi penggalian lan nyuda produksi.

Kita-gudang1

Pack lan ngirim

- Aerial Boom Lift

- China Dump Truck

- Daur ulang kadhemen

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Lampiran Forklift Sweeper

- Bagian Bulldozer Hbxg

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Liugong Bulldozer Parts

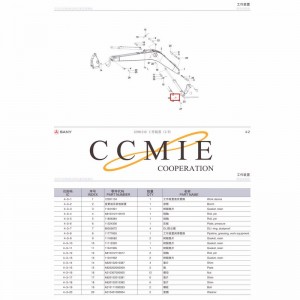

- Spare Parts Pompa Beton Sany

- Spare Parts Sany Excavator

- Suku Cadang Mesin Shacman

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Nyambung Poros Pin

- Shantui Bulldozer Kontrol Poros Fleksibel

- Shantui Bulldozer Poros Fleksibel

- Shantui Bulldozer Lifting Cylinder Repair Kit

- Shantui Bulldozer Parts

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Spare Parts Shantui Bulldozer

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer ngarep Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Majelis Pintu Shantui Sd16

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Bearing Lengan

- Shantui Sd22 Gesekan Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Truk Derek

- Xcmg Bulldozer Parts

- Spare Parts Bulldozer Xcmg

- Kunci Hidrolik Xcmg

- Transmisi Xcmg

- Yuchai Engine Parts